L210

Description

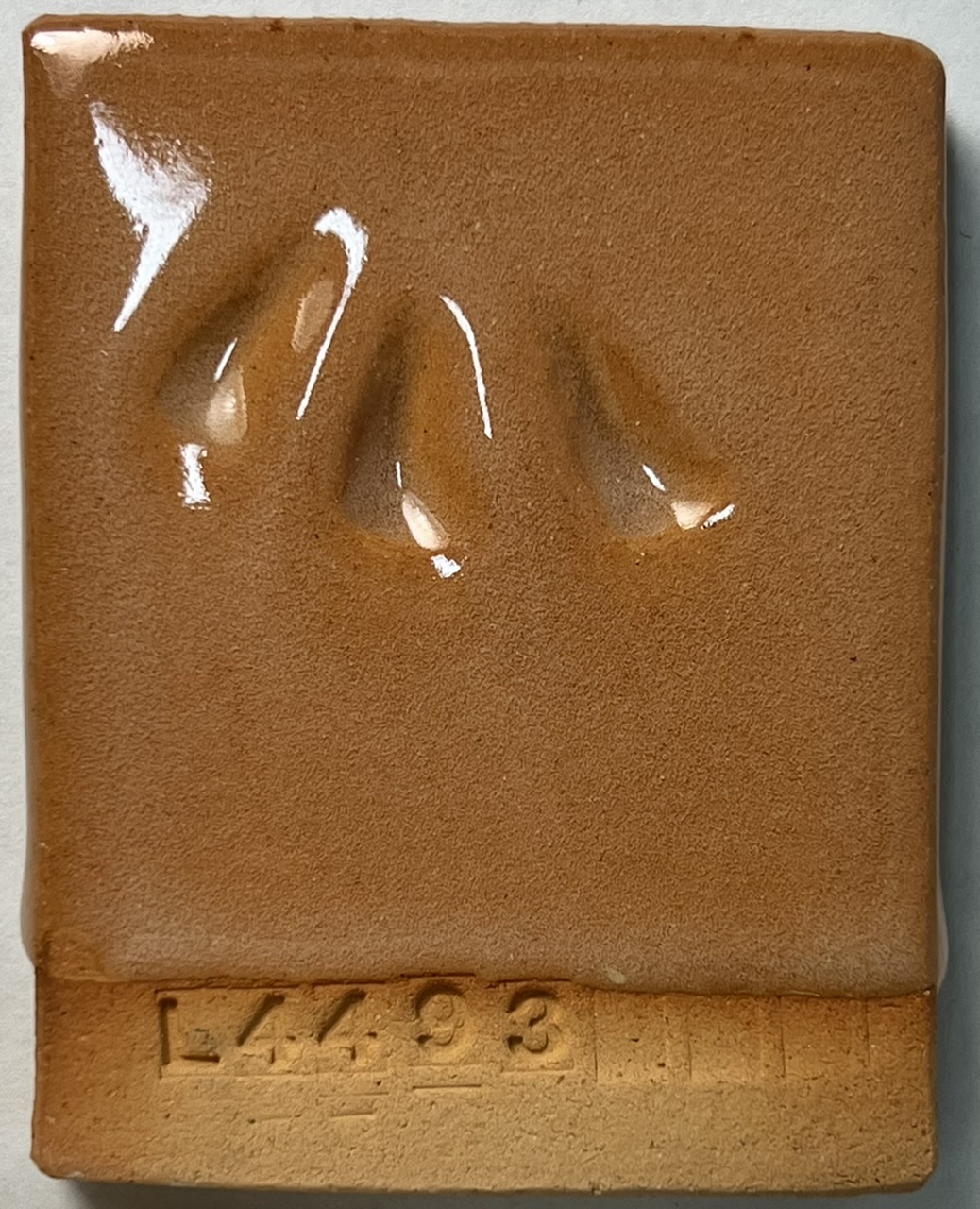

Low temperature, smooth, highly plastic, brown-burning, native terra cotta body. It fires to a stoneware at cone 2.

News

Starting with code beginning "P6984" L210 has a new recipe. The change was to remove the 10% talc that it formerly contained (we are removing talc from many other clay bodies also). You should not see an impact on glaze fit or fired color. The body remains highly plastic and very smooth. It is now also useful as a stoneware, firing stable in the cone 2-4 range.

Process Properties

Because L210 is highly plastic it also has high drying shrinkage. Please exercise caution to dry pieces evenly.

Firing

L210 fires to a light brown at cone 02-06. By cone 2 the color intensifies to a dense stoneware brown. Before cone 4 it is over fired. Like any other low-fire body at cone 06-04, L210 is fairly weak and has high porosity. But at cone 02 it is much stronger.

Glazing

L210 fires to a light enough color that bright colored glazes should work well on it. Transparent glazes can be applied thinly to produce ultra clear results.

We cannot guarantee that commercial brushing glazes will not craze or shiver, please test. Regarding toxicity: Do not assume food surface safety of brightly colored glazes in your kiln without a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

Spectrum 700 clear, 301 white, 743 red and 753 yellow on L210. Since L210 fires lighter than the traditional terra cotta red, bright-colored glazes work well on it.

Physical Properties

Drying Shrinkage: 7.0-8.0% Dry Strength: n/a Water Content: 22.0-23.0% Drying Factor: C130 Dry Density: n/a

Sieve Analysis (Tyler mesh):

+35: tr 35-48: tr 48-65: 0.1% 65-100: 3.5-4.5 100-150: 3.0-4.0 150-200: 4.5-5.5

Fired Shrinkage:

Cone 06: 0.0-1.0% Cone 04: 2.0-3.0 Cone 02: 4.5-5.5 Cone 2: 6.0-7.0

Fired Absorption:

Cone 06: 10-12% Cone 04: 8.0-10.0% Cone 02: 2.5-3.5 Cone 2: 0.5-1.5