Tapper Clay II

Description

Tapper Clay II is vacuum pugged to produce a pliable and workable material.

Popping: The tendency to fracture due to internal steam pressure associated with accelerated water discharge has been decreased in two ways:

-Less K2O: The material now has a much higher melting temperature. This reduces the formation of a glassy melt that reacts with the metallic melt to seal in crystal water.

-15% aggregate has been employed to improve venting of steam.

Injection Properties: Injection properties have been improved by increasing the proportion of plastic components and replacing the silty material with fine sand and brick aggregate. The result is greater pliability, this reduces the tendency to split and fall apart during injection.

Process Properties

Aggregate: Tapper Clay II performs a function that requires high aggregate content (sand, grog) to vent steam to prevent cracking and explosions during sudden heating. If you can tolerate the lower pliability associated with a coarser or higher percentage of aggregate please contact us.

Heating

This product performs a function that pushes clay beyond its normal limits. Clay normally requires hours to dry and it will crack or explode if pushed to dry too fast. However by adding sand and aggregate to provide small channels to vent steam the clay can be force-dried much more quickly. Most clays will form a 'glassy skin' around particles when exposed to 1200-1300C, and this further impedes the escape of steam. However our Tapper II mix is made from refractory materials that are low in K2O and Na2O and remain stable (it deforms and begins the melting process at about 1600C).

Physical Properties

Drying Shrinkage: 5.0-5.5% Water Content: 17.5-18.5 Drying Factor: C120 Service Temperature: to 1500C (PCE: 26) Bond Type: Heat Wet Density: Minimum Time Before Firing: 0 hr. Storage Life: 6 months Packaging: 20 kg box (44 lb)

Sieve Analysis (Tyler mesh):

+48 (300 microns): 6.0-8.0% 48-65 (300-210 microns): 4.0-7.0 65-100 (210-149 microns): 9.0-12.0 100-150 (149-106 microns): 3.0-7.0 150-200 (106-75 microns): 3.0-7.0 200-325 (75-45 microns): 2.0-4.0

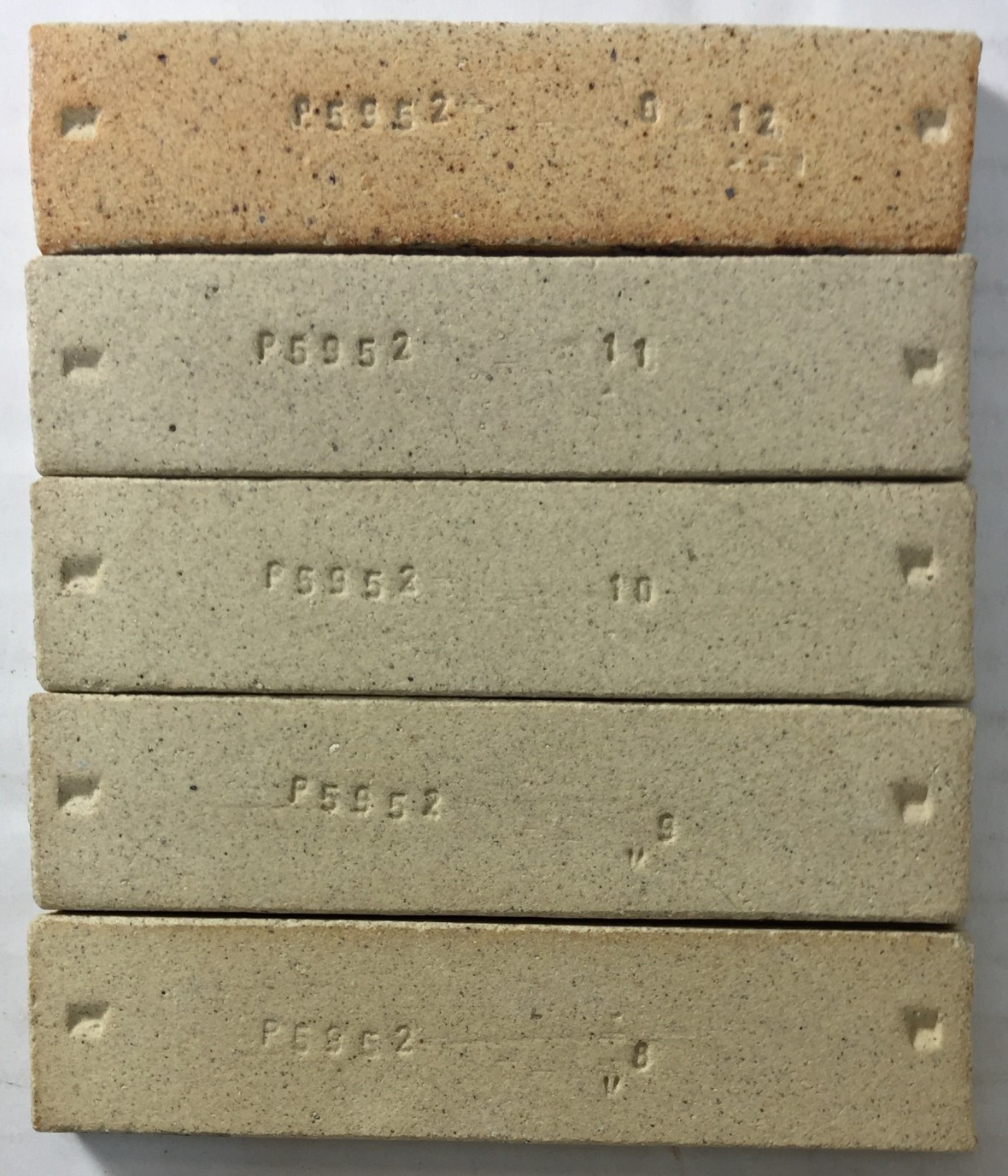

Burned Shrinkage:

1220C: 2.0-3.5%

1260C: 2.0-3.0

1300C: 2.5-3.5

Burned Porosity:

1220C: 10.0-12.0%

1260C: 8.5-10.5

1300C: 7.5-9.5