MSculp

Description

Highly grogged plastic medium to high temperature sculpture body.

This is our M340 with 28% aggregate added (14% 20 mesh grog and 14% 75 mesh silica sand).

Process Properties

This body has a much coarser grog component than our other standard grogged bodies like M332G, H440G and H441G (these other bodies contain a range of particle sizes from fine to coarse, whereas the grog in MSculp is only large particles). However this body only contains coarse grog particles.

When working with this keep in mind that while, on one hand the grog and silica sand particles terminate cracks, reduce shrinkage and vent internal water, they also reduce the dry strength and increase splitting. If you are hand building smaller things it is likely that M340 will dry just as well.

Firing

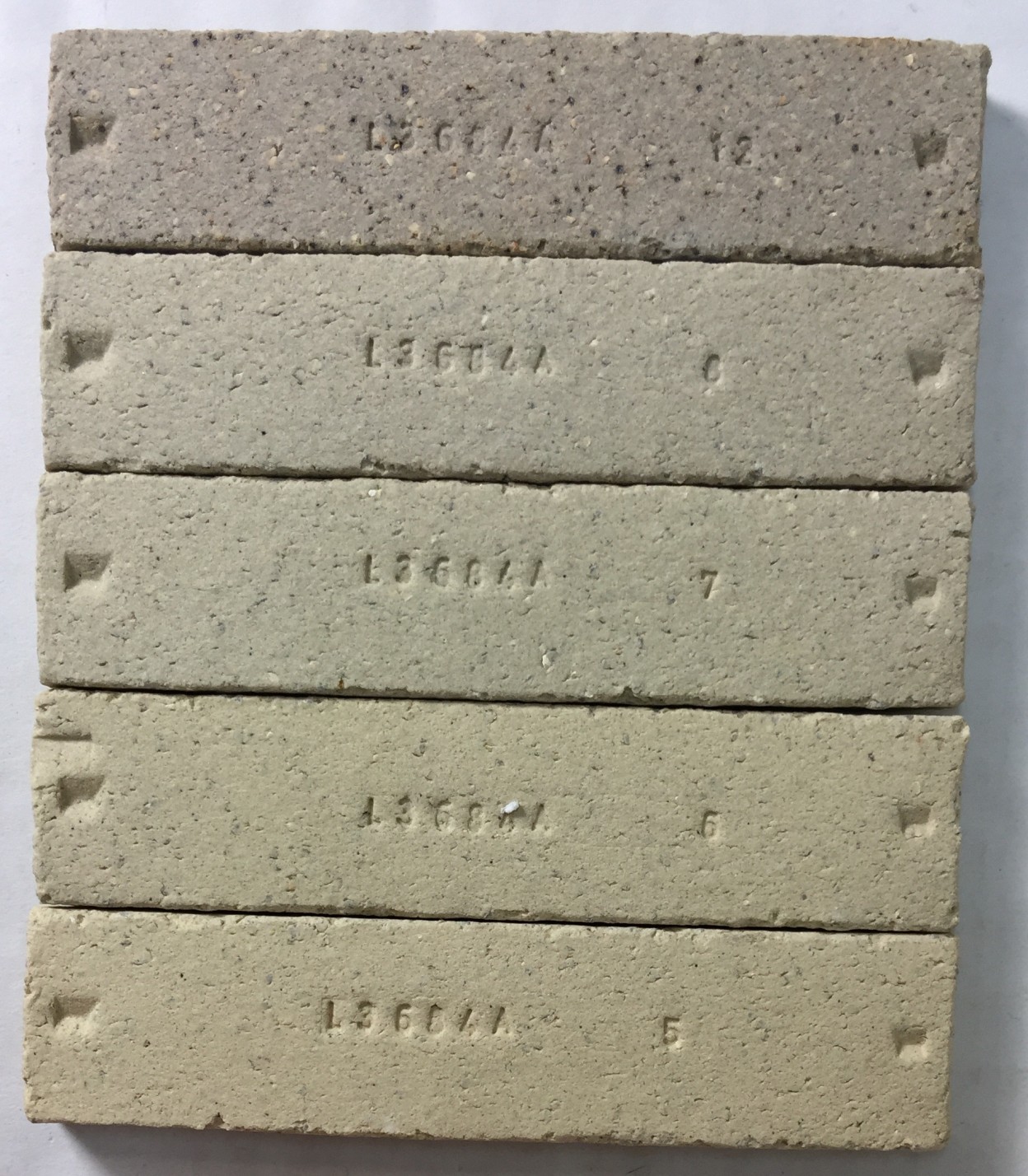

Fired color at middle temperature is a straw color similar Buffstone. At cone 10 reduction it is grey. Pieces fired at middle temperature will resist warping during firing better but they will not be as strong and will be more porous (outdoor pieces will require some sort of sealant to prevent freeze-thaw damage.

Drying shrinkage: 5% Water content: About 17% Particle size distribution: +35 mesh: 15% +48 mesh: 2% +65 mesh: 5% +100 mesh: 5% Fired shrinkage (+/- 0.5): Cone 6: 3% Cone 8: 3.5 Cone 10: 4.0 Absorption (+/- 0.5): Cone 6: 6.5% Cone 8: 5.5 Cone 10: 4.0