L215

Description

Low temperature, smooth, highly plastic, red-burning, terra cotta body. L215 is made from Plainsman M2, a natural and very clean red burning clay that we mine in Montana.

Process Properties

L215 is very plastic, it feels very smooth and you will be able to make thinner and lighter ware than ever before. It will dry very hard. Drying is now slower (giving students more time to work on their projects). Of course, the greater plasticity is accompanied by a drying shrinkage increase, so care is needed to avoid cracking (assure pieces dry evenly throughout the process).

Firing

While many people fire to cone 06, at that temperature bodies are weak and porous and some commercial glazes don't melt quite well enough. Cone 04 is more dense and considerably stronger and glazes bond better. By cone 02 L215 is almost a stoneware, however, it also generates more gases and so glazes will cloud more.

L215 fired test bars. New 2022 L215 (left) vs old talc-containing L215 (right). Cone 4, 2, 02, 04 top to bottom.

For dip-glazing adjust bisque temperature to have the needed absorbency (as low as 1750F).

To get the best defect-free surface please consider using the drop-and-hold slow-cool 04DSDH firing schedule.

Glazing

Since L215 burns red brightly-colored glazes will be somewhat muted. For the classic terra cotta red appearance through a transparent glaze, the glaze will need to be applied as thinly as possible (try ones from different vendors to get the best results).

We cannot guarantee that commercial brushing glazes will not craze or shiver, please test. Regarding toxicity: Do not assume food surface safety of brightly colored glazes in your kiln without a leach test (e.g. GLLE test). Consider using a transparent or white liner glaze for food surfaces.

Although commercial bottled products are expensive, they are most convenient. For higher production it is practical to make your own dipping or brushing base glazes that dry faster and do not craze or shiver. Our G1916Q and G3879 and recipes may be a good starting point.

When clear-glazing an important issue is glaze thickness. The mug on the left was double-dipped (so suspended bubbles are present in the handle recess, thumb-hold and along its edges). The glaze needs to be thick enough so that it feels glassy smooth but thin enough to avoid the bubbles. Normally, if applied the thickness of the one on the left, it would be completely milky, filled with micro-bubble clouds.

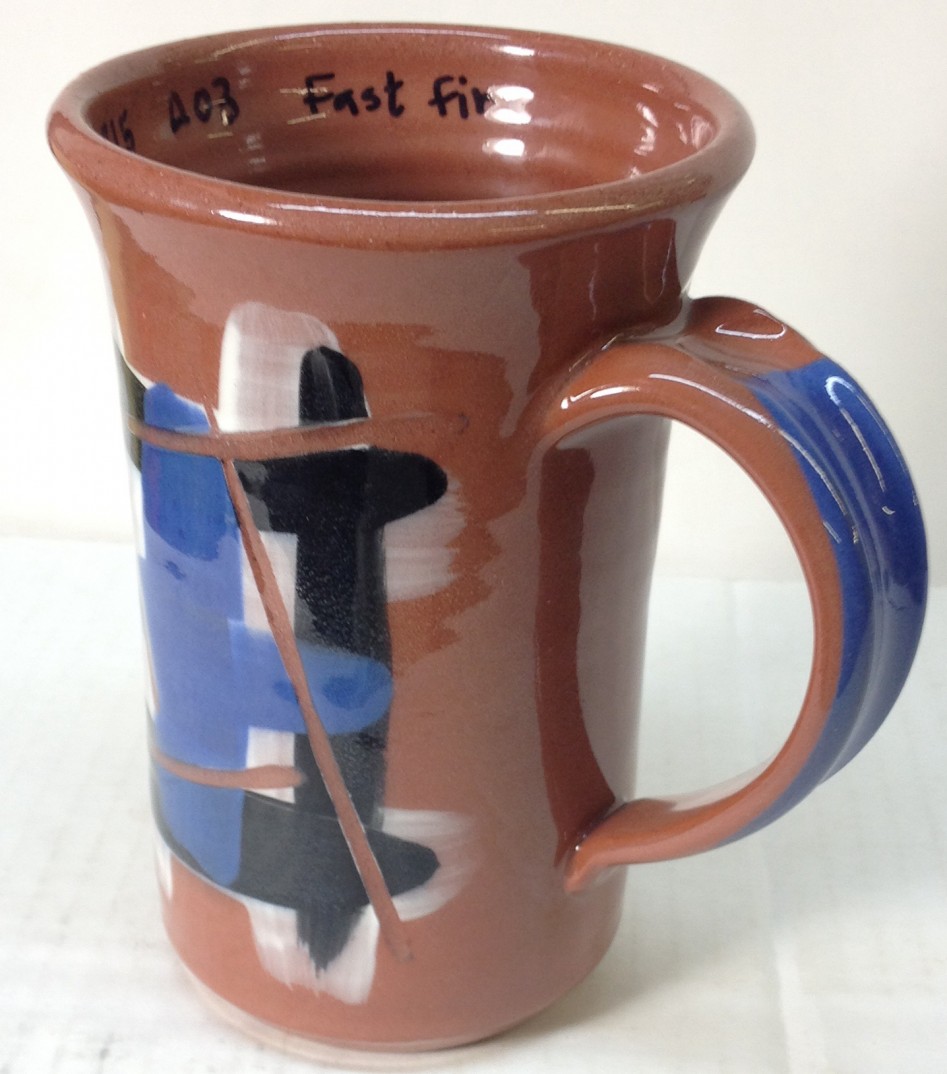

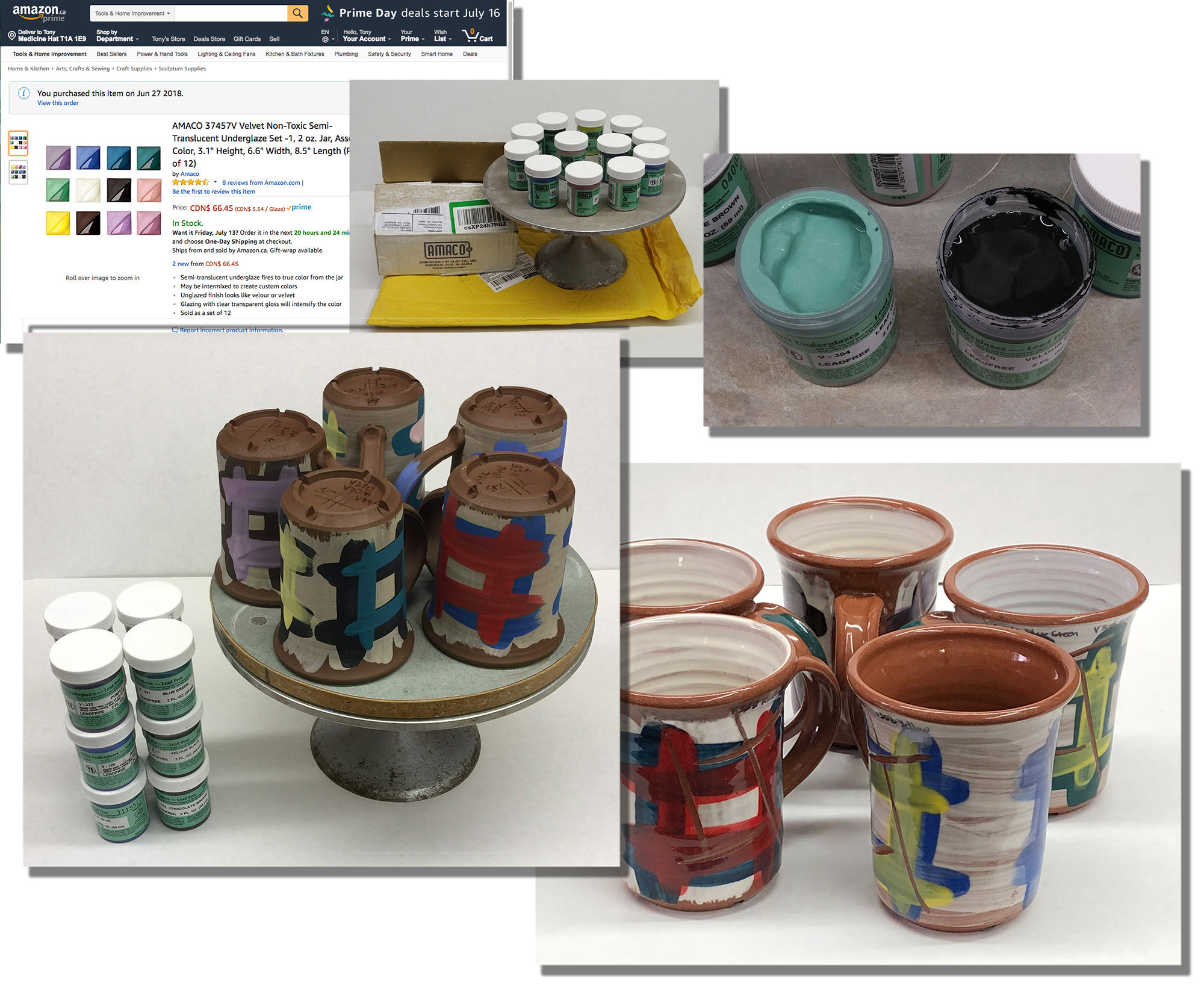

12 colors of Amaco Velvet underglazes. L3685U white slip was applied first (the velvet white would also work), then strokes of each of the colors. Bisque fired to 1750F (to achieve sufficient porosity) and then dipped each in clear glaze and fired to cone 03 (C03DRH schedule).

Spectrum 700 clear, 301 white (which is shivering), 743 red on L215 and 753 yellow on L210. Since L210 fires lighter than the traditional terra cotta red, bright-colored glazes work better on it.

Casting Recipe

We are developing a casting version of L215 with matching engobe and glaze. It is code numbered L4170B. It fires to a similar color and the recipe is flexible so you can adjust plasticity vs casting rate.

Recipe

Starting with code beginning "P6983" (March 2022) L215 has a new recipe. The change was to remove the 10% talc and commercial ball clay, replacing them with our 3D silty clay and BGP, a low temperature plastic terra cotta (we are removing talc from many other clay bodies also). You should not see an impact on glaze fit or fired color. The body remains highly plastic and smooth (but not as smooth as L210).

Thermal Expansion

We do not supply thermal expansion values. If a chart is supplied here, please view it only as a way to compare one body with another. Please note that, although you may calculate the thermal expansion of a glaze, this cannot be done for clay bodies since they do not melt. The best way to fit glazes to clay bodies is by testing, evaluation, adjustment and retesting. For example, if a glaze crazes, adjust its recipe to bring the expansion down, fire a glazed piece and thermal stress it (using an IWCT test, 300F into ice-water). If it still crazes, repeat the process.

Physical Properties

Drying Shrinkage: 6.5-7.5% Dry Strength: Very high Water Content: 20.5-21.5% Drying Factor: C130

Sieve Analysis (Tyler mesh):

+48: 0.5-1.0% 48-65: 1.0-2.0 65-100: 0.5-1.5 100-150: 1.0-2.0

Fired Shrinkage:

Cone 04: 0.75-1.25% Cone 02: 4-5 Cone 2: 5-6

Fired Absorption:

Cone 06: 12-14% Cone 04: 10-12 Cone 03: 7-8 Cone 02: 4-5 Cone 2: 2-3

Gallery

L215 with G1916Q clear 2% iron oxide (given the piece a redder hue), fired using the 04DSDH schedule. The piece is glazed on the bottom and fired on a three-pointed-stilt. Strength is excellent.

G1916Q dipping glaze + 2% iron oxide on L215. These were fired at cone 03, 05 using the 04DSDH schedule. The cone 03 version has tiny dimples on the surface, almost too small to see (likely decomposition in the body is generating bubbles).